As the official airline sponsor of the Seattle Kraken, Alaska Airlines planned to unveil another epic, Kraken-themed aircraft to get fans pumped for the 2024 NHL season.

How do you create advertising and promotional materials before the plane is available? By going virtual. I partnered with the Alaska Airlines Brand Studio to bring their livery design to life.

My 3D workflow enabled designers to fulfill print and motion graphics projects that required shots of the plane from multiple camera angles and focal lengths. After fulfilling the Kraken request, my work was expanded for a stadium wrap and broadcast planning.

An artist's canvas that soars.

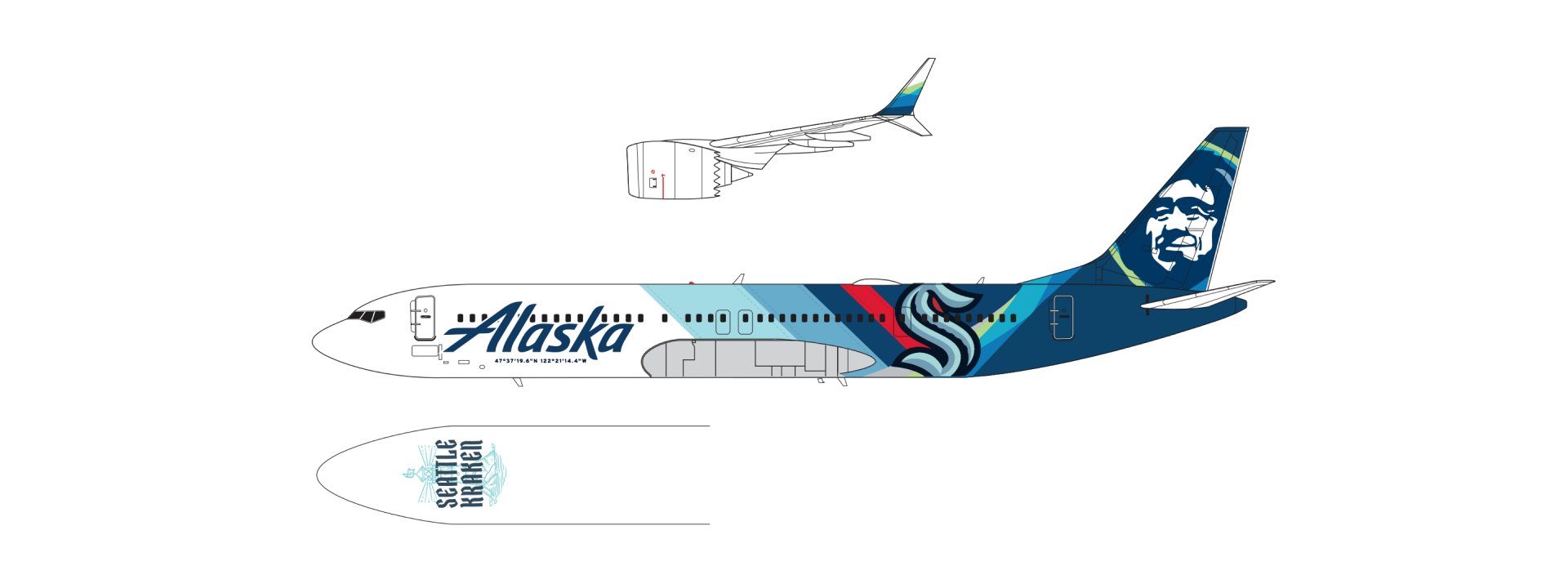

Alaska Airlines Brand Studio’s beautiful aircraft livery is the second of its unique designs for the Seattle Kraken. Advertising and sponsorship projects needed photos of the plane with its new look. However, the plane was unavailable while undergoing the update.

In the past, photos of Alaska Airlines planes required heavy image editing to visualize new liveries. This meant that designers sifted through image libraries to find photos of the plane at desired angles. Also, meticulous work was required to place 2D livery design onto every photo of the plane, matching the camera angle, lighting, and other factors.

The Brand Studio saw an opportunity and invited me to participate. My 3D workflow creates the aircraft with livery in a virtual studio. It enables designers to fulfill a spectrum of projects for print and digital graphics. They can work with me to achieve customized shots from multiple camera angles and focal lengths, with depth of field, lighting, and more.

New livery application in the hangar.

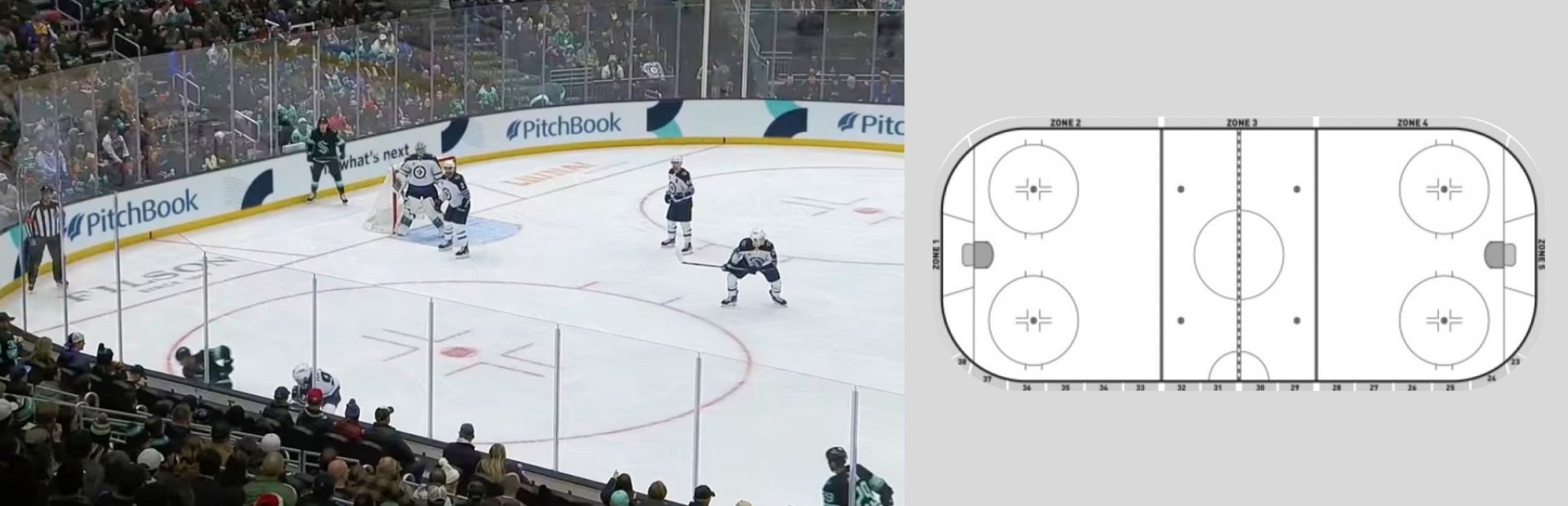

Inside a suite in the Climate Pledge Arena, a 16-square-foot area of the ceiling will display the airplane.

It will appear as if the Alaska Airlines plane with new Kraken livery is flying overhead.

Around the rink of the Climate Pledge Arena, digital billboards will display Alaska Airlines advertising.

The Alaska Airlines plane with new Kraken livery will appear in a takeoff pose.

Seattle Kraken livery design by the Brand Studio.

Assessment

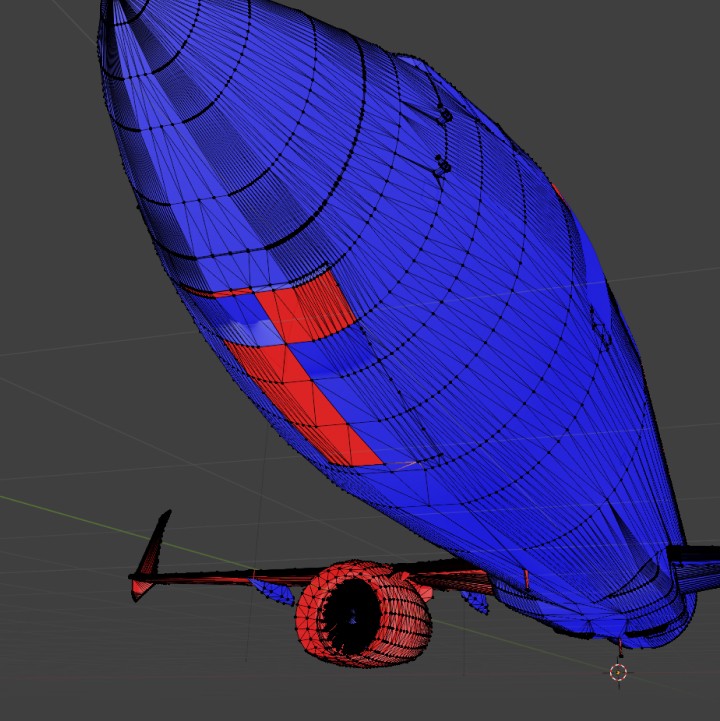

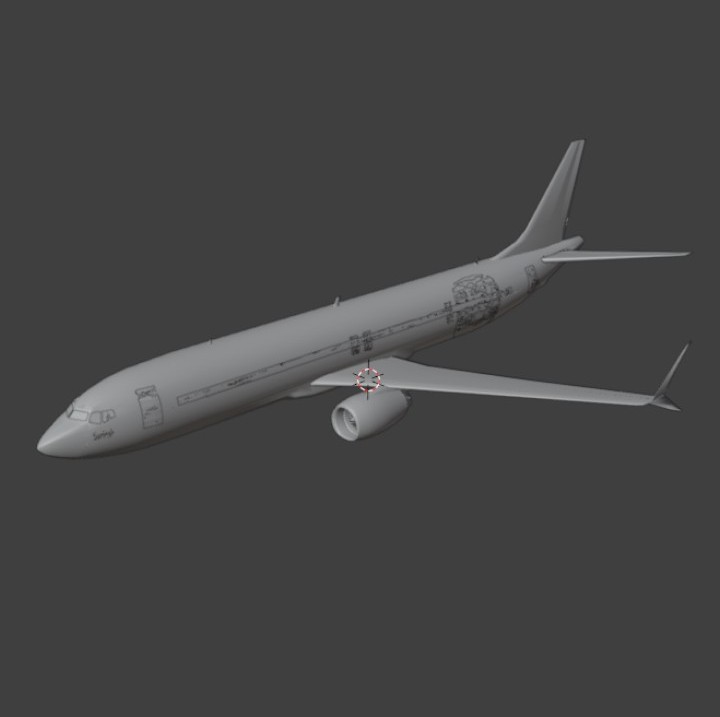

I needed a new, high-poly 3D model of a Boeing 737-9 MAX airplane with materials and decals.

In addition:

Working With Topology

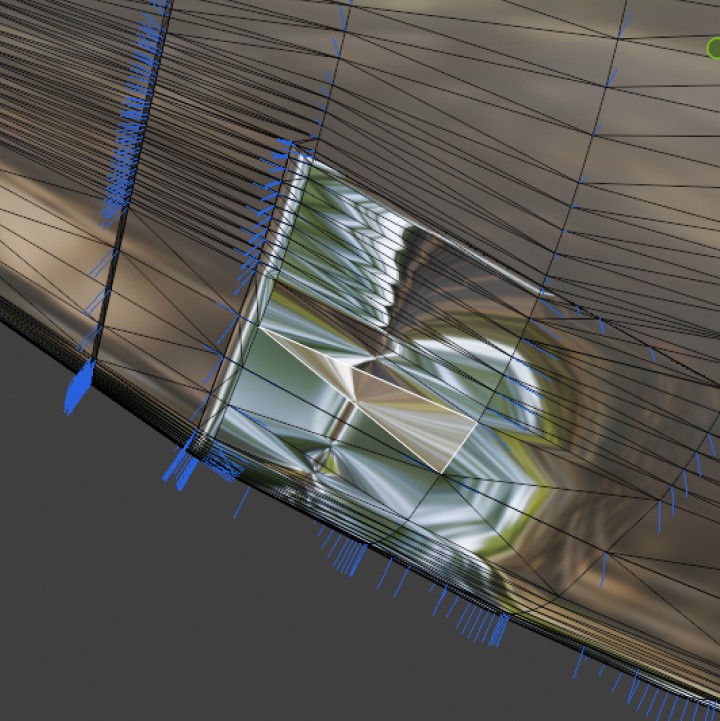

I obtained a 3D model of an untextured Boeing 737-9 MAX that appeared flawless at first glance. Once I began applying textures and decals, it became apparent that there were issues with topology and normals. This is the perfect example of why proper 3D modeling and topology are essential for a project.

I briefly entertained the idea of modeling a plane from scratch. But that’s not ideal when others are depending on me and have a short timeframe. The most efficient way forward was to quickly correct 90% of the problems, and solve for the remaining 10% by doing as filmmakers always say... “Fix it in post!”

I focused on major visible areas. I flipped normals, fixed ngons, adjusted stretched sections, and combined duplicate vertices. It was tedious, but it led to a quick solution! There’s potential for AI to solve topology problems so artists can get back to creating.

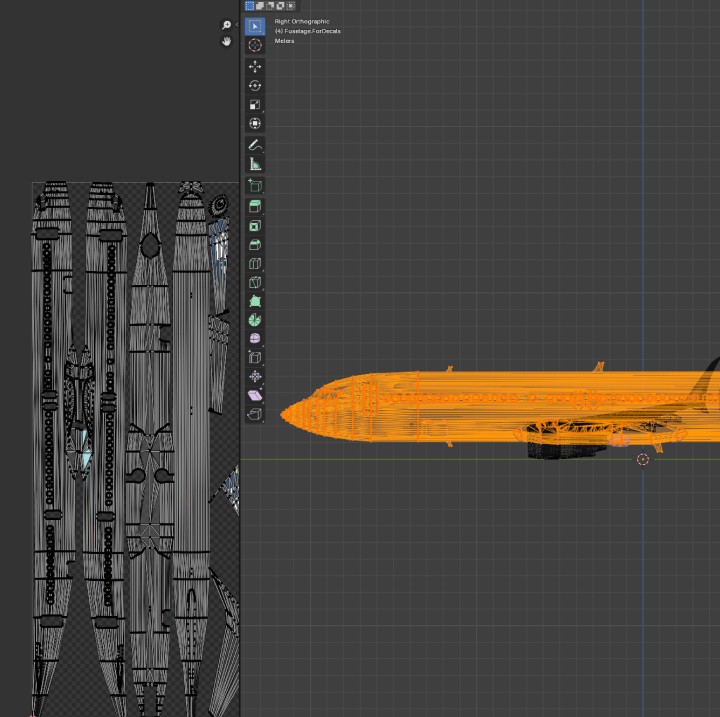

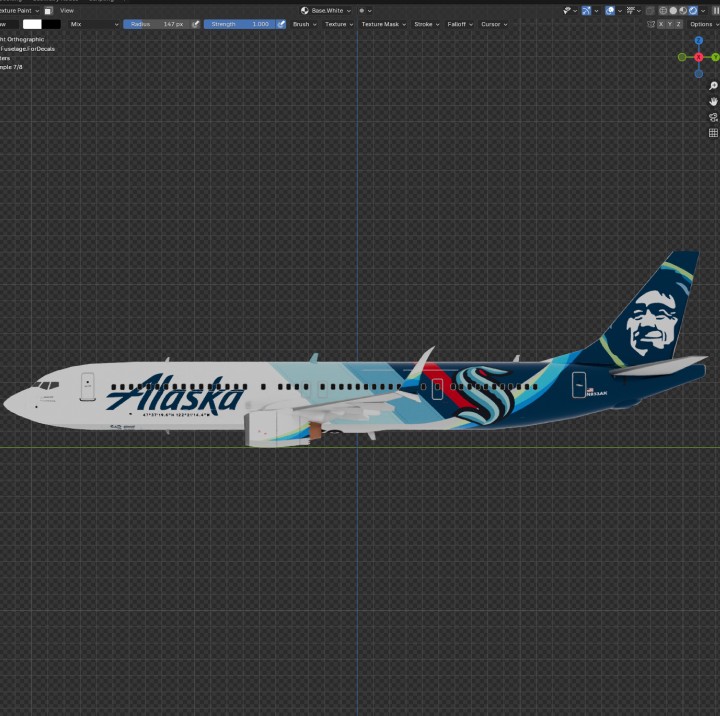

Creating Materials & Textures

With the topology tackled, the fun could begin! The first step was preparing the 3D model for the 2D livery design. I split the model into grouped sections that made the most sense for applying flat graphics. The port side fuselage and vertical stabilizer could receive nearly all of the livery. Then the port side wings and engines. These can be mirrored to achieve symmetry.

I quickly UV-unwrapped the model’s parts by either projecton- or view-based settings. Then I imported wireframe guides into my design application. Then it was a matter of aligning the vectors of the Brand Studio’s livery design and exporting the graphics as textures.

The model parts were textured via these three main methods:

Large portions of the 2D livery was painted on via X and Z perspectives. Layers of textures were achieved via nodes. Seams where textures meet were blended with texture editing. And decals were used for doors and windows that sat on top of the textures. This was also a way to make these elements easily positioned and resistant to topological anomalies.

I set up camera angles and focal lengths to match comps for each project. After rendering each image, I retouched them to fix the minor aforementioned issues.

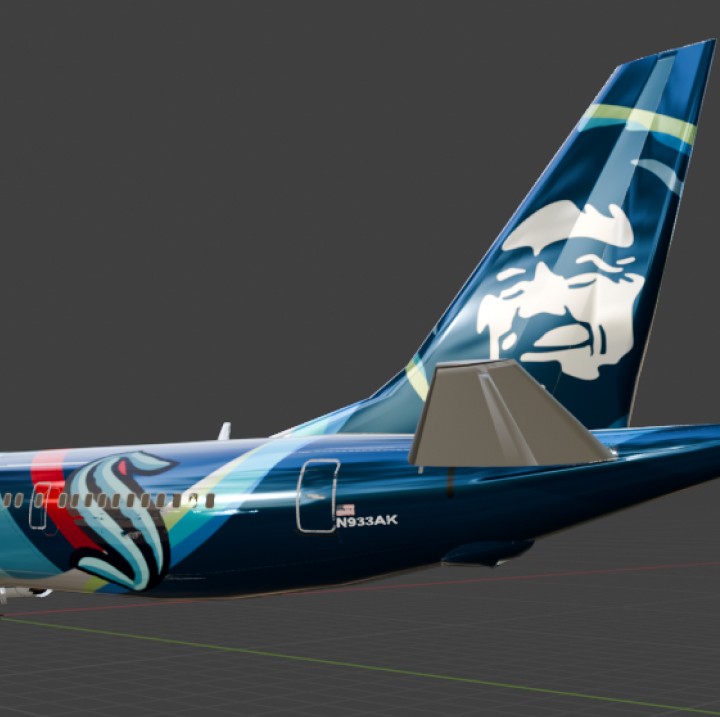

Final 3D renders of the aircraft with Seattle Kraken livery.

The final deliverables were a 13,000 x 13,000-pixel image for large-format printing and an HD image for the digital billboards. The Brand Studio and I couldn’t be happier with the results! In fulfilling these projects, we also successfully proved out my 3D workflow that I brought to Alaska Airlines.

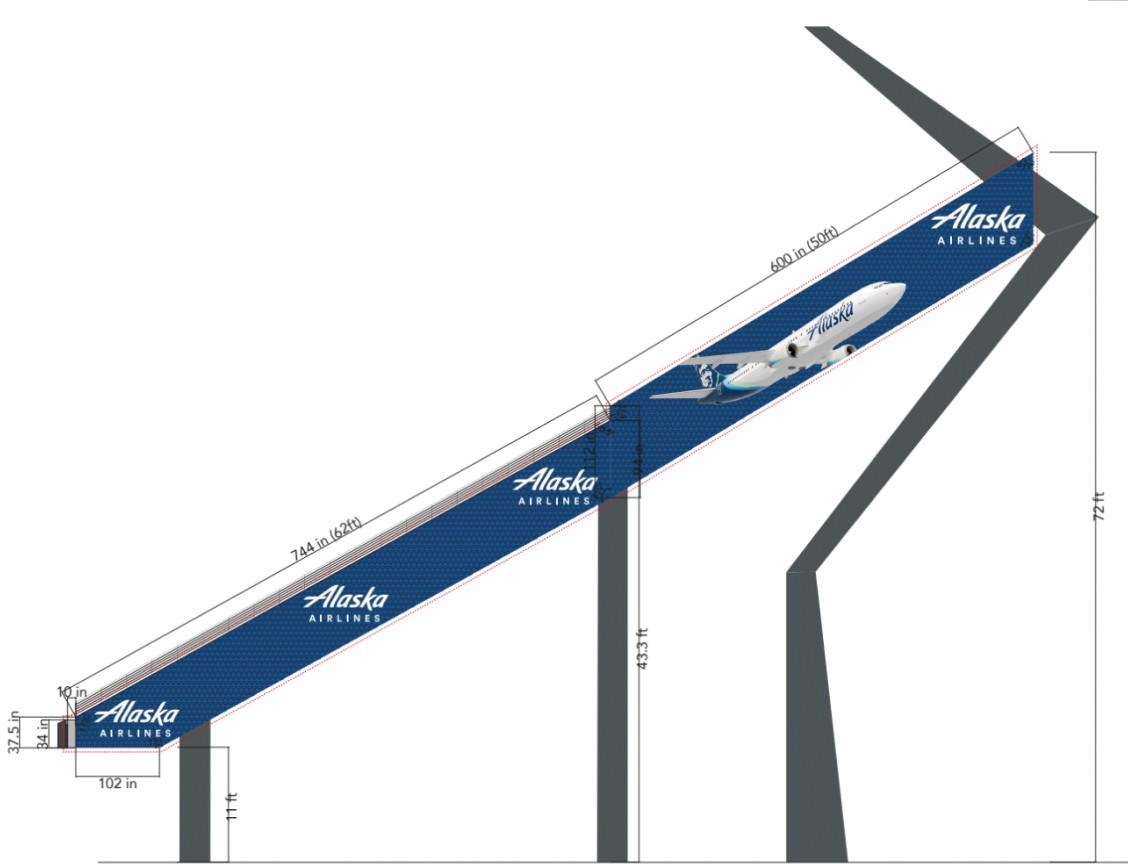

I was asked to follow up with a 3D model of an Alaska Airlines plane with standard livery. By quickly repurposing the Seattle Kraken model, I completed the second request in half the time. This would go on to be an even larger print to wrap the Snapdragon Stadium in San Diego, CA.

As a bonus, word spread of this achievement, and my 3D airplanes were used for other projects. Presentations and web product designs repurposed the imagery. Also, when Hawaiian Airlines joined the Alaska Airlines family, a dual-company event needed to feature both brands' aircraft. My plane was used for 3D previsualization to stage real aircraft tail-to-tail for the live broadcast.

Final DED advertising during an NHL broadcast game.

Large-format print of the Seattle Kraken plane flying overhead in an arena suite.

Later reveal of the real plane with the Seattle Kraken livery.

3D render of the standard Alaska livery.

3D render of the Seattle Kraken livery.

3D render of the standard livery, port side view.

3D render of the Seattle Kraken livery, port side view.

Snapdragon Stadium wrap design with my 3D plane.

Live event, previsualized using my 3D models.